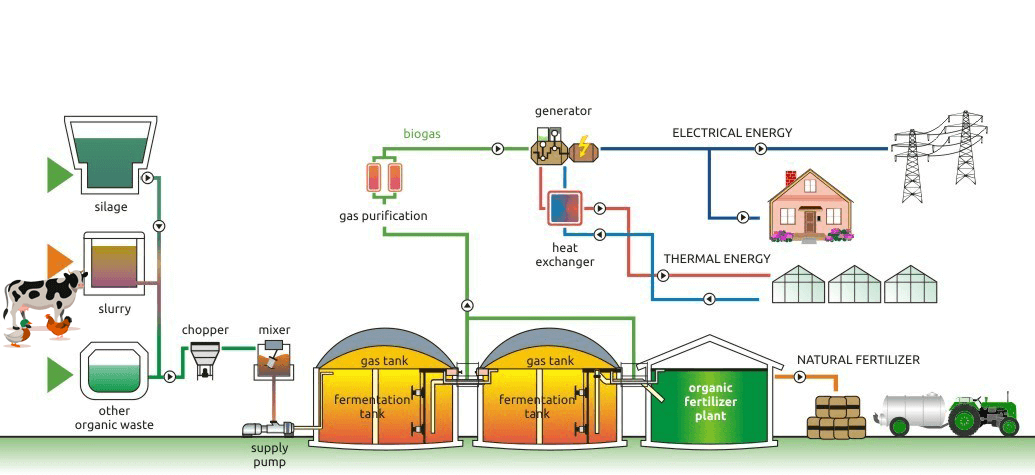

Plant silages are added

1 of 16Liquid fertilizer front tank

2 of 16It is added in other organic wastes.

3 of 16Wastes break down

4 of 16Waste is mixed

5 of 16The waste is sent to the tanks by the feed pump

6 of 16Waste is kept for fermentation in the fermentation tank

7 of 16Gas is formed as a result of fermentation

8 of 16turns into biogas after gas purification

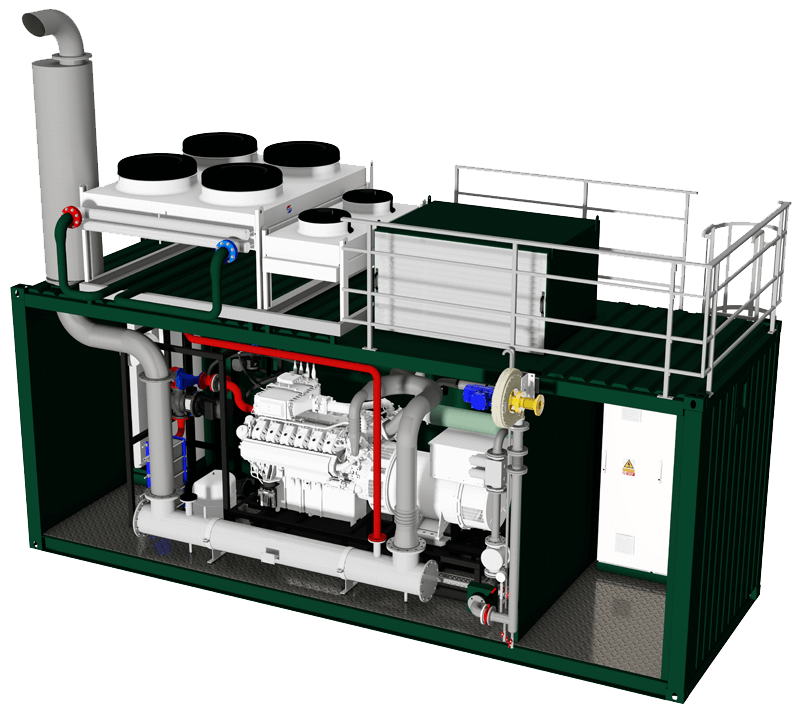

9 of 16Electricity is produced by burning biogas

10 of 16The generated electricity is sold to the grid

11 of 16Generated electricity is used in homes

12 of 16The heat released is sent to the exchangers

13 of 16The heat energy released is used in greenhouse and residential heating, vegetable, fruit, corn drying and cooling.

14 of 16Fermentation waste

It is taken to the organic fertilizer tank.

Liquid / Solid organic fertilizers are produced.

The organic fertilizers formed are ready to use.

16 of 16We work for you ...

Livestock businesses and food production establishments;

- Dairy and livestock breeding enterprises of 500 or more cattle,

- 1500 small heads and more closed livestock enterprises,

- Food production enterprises,

- Canned food factories,

- Juice businesses

- Pickling businesses,

- Villages in residential areas with intensive livestock breeding,

Local governments with a population above 5,000 individuals;

- Recycling projects for the production of organic fertilizers with energy and humus from plant and biological waste in accordance with the “ZERO WASTE” law

Investors, entrepreneurs;

- Consultancy services for recycling and energy generation projects development, planning, projecting and implementation within the scope of Private and Public-Private Partnerships (PPP).